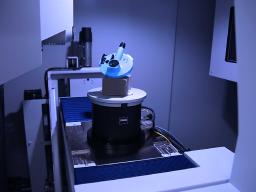

Product inspection plays a critical role in modern manufacturing, ensuring components meet strict quality, safety, and performance standards. As products become more complex, traditional inspection methods often struggle to detect internal defects or measure hidden features. This is where industrial CT scanning is transforming product inspection.

By providing detailed 3D images of both internal and external structures, industrial CT scanning allows manufacturers to inspect components thoroughly without causing damage. In this article, we explain how this advanced technology improves product inspection, reduces risk, and supports better decision-making across industries.

Industrial CT scanning (computed tomography) is a non-destructive testing method that uses X-rays to capture multiple images of an object from different angles. These images are digitally reconstructed into a high-resolution 3D model, allowing inspectors to view internal features that are otherwise impossible to access.

Unlike traditional inspection tools that only measure surface features, industrial CT scanning provides complete visibility of a component’s internal geometry, material integrity, and structural consistency.

Conventional inspection techniques such as calipers, gauges, and coordinate measuring machines (CMMs) are effective for surface measurements, but they have limitations:

Internal defects cannot be detected without cutting the part

Complex internal geometries are difficult to measure

Multiple inspections may be required using different tools

Destructive testing results in wasted components

As manufacturing tolerances tighten and designs become more intricate, these limitations can lead to missed defects, costly rework, or production delays.

One of the biggest advantages of industrial CT scanning is its ability to inspect both internal and external features simultaneously. This allows manufacturers to identify:

Internal voids and porosity

Cracks and material inconsistencies

Assembly misalignment

Hidden dimensional inaccuracies

This level of visibility ensures a more reliable and thorough inspection process.

Because industrial CT scanning is non-destructive, components remain intact after inspection. This is especially valuable for:

High-value parts

Prototype validation

Safety-critical components

Low-volume or custom manufacturing

Manufacturers can inspect parts without sacrificing them, reducing waste and preserving product integrity.

Industrial CT scanning allows precise dimensional analysis of complex components, including internal features that cannot be measured using traditional tools. Measurements can be taken directly from the 3D model, supporting:

Tolerance verification

First article inspection

Reverse engineering

CAD model comparison

This improves confidence in product quality and design accuracy.

By combining multiple inspection tasks into a single scan, industrial CT scanning streamlines quality control workflows. Instead of using several inspection methods, manufacturers can perform comprehensive checks in one process, saving time and reducing production delays.

Faster inspections mean quicker feedback, enabling manufacturers to correct issues early and maintain production schedules.

Detecting defects early is essential to preventing costly failures later in the production cycle. Industrial CT scanning identifies problems at an early stage, allowing corrective action before components reach assembly or shipment.

This proactive approach improves product reliability and reduces the risk of recalls or customer complaints.

Industrial CT scanning is widely used across industries where precision and quality are critical, including:

Aerospace and aviation

Automotive manufacturing

Medical device production

Electronics and micro-components

Additive manufacturing

Each of these sectors relies on accurate inspection to meet regulatory standards and customer expectations.

Beyond quality control, industrial CT scanning supports product development and continuous improvement. Engineers can analyse scan data to optimise designs, improve manufacturing processes, and validate new materials or techniques.

This insight-driven approach helps businesses innovate while maintaining consistent quality.

Industrial CT scanning has become an essential tool for improving product inspection in modern manufacturing. By offering complete internal visibility, non-destructive testing, accurate measurement, and faster inspection times, it overcomes the limitations of traditional methods.

As products continue to evolve in complexity, industrial CT scanning provides manufacturers with the confidence, precision, and efficiency needed to deliver high-quality components every time.

| No comments yet. Be the first. |