Definition and Core Functionality

Form-Fill-Seal (FFS) machines are sophisticated automated systems that streamline the packaging process by forming, filling, and sealing products in a continuous sequence. These machines mitigate human intervention, ensuring precision, sterility, and efficiency. From flexible pouches to rigid containers, their versatility caters to a myriad of industry needs.

For more info please visit: https://market.us/report/global-form-fill-seal-machines-market/

Evolution and Technological Progression

The genesis of FFS machines traces back to the mid-20th century, evolving from rudimentary mechanical systems to advanced servo-driven units with precision control. Over time, integration with digital interfaces and adaptive software has transformed them into intelligent packaging solutions capable of self-diagnosis, predictive maintenance, and adaptive sealing parameters.

Rising Automation in Packaging Processes

Industries across the globe are embracing automation to enhance throughput and minimize operational errors. FFS machines epitomize this trend, delivering seamless production cycles, reduced downtime, and consistent packaging quality.

Demand Surge in Food, Beverage, and Pharmaceutical Sectors

The escalating consumption of packaged foods, ready-to-drink beverages, and over-the-counter pharmaceuticals is amplifying the adoption of these machines. Their ability to maintain product integrity while accelerating packaging speed makes them indispensable in high-demand sectors.

Sustainability and Eco-Conscious Packaging Initiatives

The push towards environmental stewardship is influencing packaging formats. Modern FFS machines are engineered to accommodate recyclable films, biodegradable laminates, and minimalistic packaging designs, aligning with global sustainability objectives.

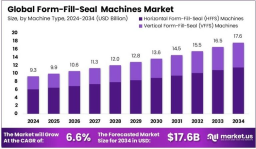

Vertical vs. Horizontal Form-Fill-Seal Machines

Vertical FFS machines excel in handling granular and powdered products, leveraging gravity-assisted filling mechanisms. In contrast, horizontal FFS units cater to solid, semi-solid, and irregularly shaped items, offering more flexibility in package design.

Application-Based Differentiation

From condiments and confectioneries to detergents and fertilizers, the adaptability of FFS machines spans across sectors. Specialized modules enable the packaging of both perishable goods requiring hermetic seals and industrial products demanding robust containment.

Regional Market Disparities

While North America and Europe exhibit mature adoption rates driven by technological sophistication, Asia-Pacific is experiencing rapid market acceleration fueled by industrial expansion and rising consumerism. Latin America and Africa, though emerging, are demonstrating promising growth trajectories.

Integration of IoT and Smart Monitoring

Modern FFS machines incorporate IoT-enabled sensors that provide real-time data on temperature, sealing pressure, film tension, and operational speed. This fosters predictive maintenance, reducing unplanned downtime and optimizing productivity.

Advanced Sealing Mechanisms and Material Compatibility

Innovations in sealing technologies, such as ultrasonic and impulse sealing, enhance the ability to work with diverse packaging materials, including heat-sensitive and multilayer films. These advancements ensure airtight seals without compromising material integrity.

Customization Capabilities for Diverse Industries

The demand for unique packaging formats has led to the proliferation of modular FFS systems. These customizable configurations allow manufacturers to switch between different product lines with minimal changeover time.

High Capital Expenditure and Maintenance Costs

The sophisticated engineering behind FFS machines comes with substantial upfront investment. For small and medium enterprises, this financial barrier can be prohibitive.

Operational Complexity and Skilled Labor Shortage

Operating advanced FFS units necessitates skilled technicians capable of troubleshooting mechanical, electronic, and software-related issues. A shortage of trained personnel can impede operational efficiency.

Regulatory Compliance and Packaging Standards

Compliance with stringent packaging standards, particularly in the pharmaceutical and food sectors, demands continuous machine calibration, documentation, and certification, which can add operational burden.

For more info please visit: https://market.us/report/global-form-fill-seal-machines-market/

Adoption of Biodegradable and Compostable Films

As environmental legislation tightens, FFS machines will increasingly pivot towards materials that degrade naturally, without leaving toxic residues. This transition represents a lucrative growth avenue for manufacturers aligning with eco-conscious trends.

Emerging Markets and Untapped Industrial Segments

Expanding into developing economies presents substantial opportunities. Rapid industrialization and urbanization are creating demand for efficient, scalable packaging solutions.

Strategic Collaborations and R&D Investments

Collaborations between packaging machine manufacturers, material scientists, and industry stakeholders will accelerate innovation. Enhanced R&D investments will lead to machines with higher efficiency, lower energy consumption, and greater adaptability.

| No comments yet. Be the first. |