The Critical Importance of Ship Maintenance in Global Maritime Operations

The ocean does not forgive neglect. In the world of maritime logistics, ship maintenance is not a discretionary practice—it is a vital imperative. Ships are floating ecosystems, exposed to ceaseless elemental assault: saline corrosion, mechanical fatigue, and biofouling. Without systematic upkeep, even the most formidable vessel becomes a liability. From container giants traversing intercontinental routes to agile naval crafts maneuvering in conflict zones, maintenance underpins operational integrity and safety. In a global economy where over 80% of trade by volume travels by sea, ship maintenance serves as the unsung backbone of international commerce.

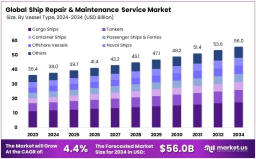

For more info please visit: https://market.us/report/ship-repair-and-maintenance-service-market/

Preventive Maintenance: Avoiding Catastrophic Failures

Preventive maintenance is the cornerstone of maritime asset longevity. It is proactive in nature—inspections, lubrication, system recalibration, and parts replacement are performed before any failure occurs. This discipline reduces the risk of sudden breakdowns mid-voyage, where delays are costly and repairs are impractical. Scheduled dry docking, routine engine overhauls, and antifouling paint applications are classic examples. The purpose is not just operational continuity, but also compliance with classification societies and port-state control mandates.

Corrective Maintenance: Fixing What’s Broken

Corrective maintenance enters the frame when equipment or structural elements fail. This reactive approach may range from swapping a burned-out navigation light to replacing a fractured crankshaft. While it is unavoidable in a vessel’s lifecycle, corrective maintenance is generally more expensive and logistically disruptive. Repairs often occur under tight timelines, either in port or during anchorage—requiring skilled intervention and often, temporary system shutdowns.

Predictive Maintenance: Leveraging Data for Efficiency

Predictive maintenance is the most advanced form of upkeep, leveraging sensor data and machine learning algorithms to forecast equipment wear before failure occurs. Vibration analysis, thermal imaging, and real-time fluid diagnostics provide early warnings. The integration of Internet of Things (IoT) devices aboard modern vessels enables dynamic maintenance schedules, optimizing resource allocation and reducing downtime. This strategy epitomizes the shift toward smart shipping and digital fleet management.

Dry Docking and Hull Repairs

Dry docking is the surgical theater of ship repair. Vessels are brought to a halt, drained of surrounding water, and subjected to rigorous inspection. The hull—constantly subjected to stress and corrosion—is scraped, sandblasted, and coated with new layers of protection. Cracks are welded, steel plates replaced, and ballast tanks cleaned. This procedure, often occurring every five years, rejuvenates a vessel’s structural integrity and hydrodynamic efficiency.

Propulsion System Overhaul

A ship’s propulsion system is its heart. Main engines, shafts, gearboxes, and thrusters must be meticulously maintained and, when necessary, disassembled and reconditioned. Turbochargers are cleaned of carbon build-up, seals are replaced, and alignment checks are performed. Any oversight can translate into loss of thrust, increased fuel consumption, or in worst cases, complete immobilization.

Superstructure and Interior Restorations

Beyond mechanics, a ship’s superstructure and interiors endure constant exposure and use. Bridges, accommodation blocks, and cargo holds require periodic refurbishment. This includes insulation replacement, rust treatment, HVAC servicing, and sometimes, aesthetic refits for passenger vessels. Though less glamorous, these tasks are integral to operational morale, crew safety, and regulatory compliance.

Use of Robotics and Drones in Inspection

Gone are the days when every inspection required human descent into ballast tanks or external hull surveys via scaffolding. Submersible robots and aerial drones now conduct precise, high-resolution inspections in otherwise inaccessible areas. They reduce risk, accelerate surveys, and enhance accuracy—minimizing guesswork and enabling targeted interventions.

AI and IoT in Predictive Diagnostics

Artificial intelligence algorithms now parse terabytes of ship performance data to detect anomalies long before a human operator could. IoT-enabled engines, rudders, and auxiliary systems feed continuous data streams into cloud-based platforms. These systems forecast component degradation with uncanny accuracy, revolutionizing maintenance planning and reducing lifecycle costs.

Advanced Coatings and Anti-Corrosion Materials

Innovative coatings infused with graphene or silicone-based compounds are reshaping corrosion management. These high-performance materials resist biofouling, reduce drag, and extend hull life by years. Similarly, cathodic protection systems have become more efficient, using impressed current techniques to stave off galvanic decay in steel structures.

For more info please visit: https://market.us/report/ship-repair-and-maintenance-service-market/

Environmental Regulations and Compliance

Modern shipyards and operators navigate a complex maze of environmental mandates—ranging from sulfur emission caps to ballast water treatment protocols. Repairs must now align with these regulations, requiring eco-friendly materials, waste management systems, and emission control retrofits. Non-compliance risks steep penalties and detentions.

Skilled Labor Shortage and Training Gaps

Despite its critical nature, the maritime repair sector faces an acute shortage of skilled workers. Welders, marine engineers, and coating specialists are aging out, and replacements are scarce. Training institutions struggle to keep pace with emerging technologies, creating a knowledge chasm that threatens service quality and safety.

Logistical Constraints and Cost Pressures

Repair schedules are often dictated by port availability, docking space, and supply chain dependencies. Coordinating material procurement, skilled labor, and time-sensitive operations is a logistical chess game. Compounding the problem, shipping companies operate on razor-thin margins—forcing repair yards to balance cost-efficiency with technical excellence.

The Road Ahead: Sustaining Fleet Integrity in a Changing World

Ship repair and maintenance are undergoing a paradigm shift. As vessels grow larger and regulations tighten, the demand for smarter, cleaner, and more efficient solutions rises. Whether through predictive analytics, eco-conscious materials, or automation, the industry must evolve or risk obsolescence. Maintenance is no longer a matter of reactive necessity—it is a strategic function that safeguards human life, economic continuity, and environmental stewardship. The future belongs to those who can balance tradition with innovation, and who recognize that in the maritime world, resilience begins with care.

| No comments yet. Be the first. |