The SCARA Robot Market is booming. These specialized robots, known as Selective Compliance Articulated Robot Arm or Selective Compliance Assembly Robot Arm, excel at rapid, precise movements on horizontal planes, maintaining stiffness vertically. This makes them perfect for tasks demanding speed and repeatability, like assembly, material handling, and pick-and-place operations. Their rise signifies a shift towards efficient, precise automation in manufacturing worldwide.

The Rise of Precision Automation

In modern manufacturing, where speed, accuracy, and cost-efficiency are critical, industrial robots are indispensable. SCARA robots have carved a significant niche due to their unique design and operational advantages. Simpler, more compact, and often more cost-effective than complex six-axis robots, SCARAs are ideal for specific applications. Their ability to perform fast, precise movements within a cylindrical work envelope makes them a go-to choice for optimizing production lines and reducing manual intervention. The ongoing Industry 4.0 revolution further amplifies their importance.

Market Size and Growth Trajectory

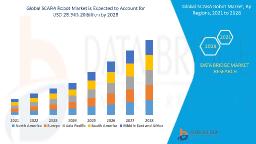

The SCARA robot market is experiencing substantial growth. Valued at approximately USD 4.7 billion in 2023, it's projected to reach an estimated USD 15.6 billion by 2032, demonstrating a robust compound annual growth rate (CAGR) of 14.29% from 2024 to 2032. Another forecast suggests a market size of USD 25.7 billion by 2033, with a CAGR of 10.8% from 2024-2033. This growth highlights increasing global investment in automation to boost productivity, improve quality, and address labor shortages.

Key Market Growth Drivers

Several factors are fueling the expansion of the SCARA robot market:

- Demand for Precision and Speed: Industries constantly seek faster, more accurate production. SCARA robots, with their high-speed capabilities and precision, are perfectly suited for repetitive tasks requiring consistency.

- Industry 4.0 and Smart Manufacturing: The adoption of Industry 4.0 initiatives—emphasizing interconnected smart factories and real-time data—is a major catalyst. SCARA robots integrate seamlessly into these advanced manufacturing ecosystems, enhancing efficiency.

- Increasing Automation Needs: Labor shortages and the drive to cut costs push manufacturers towards automation. SCARA robots offer a cost-effective solution for automating assembly lines, material handling, and other repetitive tasks, boosting productivity and reducing human error.

- Growth in Electronics and Semiconductor Manufacturing: This sector is a primary driver. Miniaturization, complex circuit boards, and high demand for consumer electronics, 5G, and IoT devices necessitate precise, fast automation for assembly, pick-and-place, and wafer handling.

- Enhanced Robot Capabilities: Continuous technological advancements make SCARA robots more capable, adaptable, and easier to integrate. AI and machine learning innovations lead to smarter robots with improved performance and user-friendly interfaces.

- Supply Chain Efficiency and E-commerce Expansion: The boom in e-commerce demands streamlined logistics. SCARA robots excel in tasks like packaging, sorting, and order fulfillment in warehouses, ensuring rapid and accurate handling of goods.

SCARA Robot Market Segmentation

The SCARA robot market is segmented to provide a clearer picture of its dynamics:

- By Payload Capacity:

- Up to 5.00 kg: Dominates for its versatility and cost-effectiveness in high-speed pick-and-place, inspection, testing, and dispensing.

- 5.01 kg to 15.00 kg: Used for assembly, packaging, and lifting with increased handling.

- More than 15.00 kg: Growing for handling heavier loads.

- By Application:

- Material Handling: Dominated in 2023 for pick-and-place, sorting, palletizing, and depalletizing.

- Assembling & Disassembling: Expected to grow fastest, driven by automation in automotive, electronics, and medical devices.

- Welding and Soldering: Crucial for precision applications, especially in electronics.

- Dispensing: Ideal for high-volume and large-area tasks.

- Processing: Encompasses various manufacturing processes requiring precise manipulation.

- By End-User Industry:

- Automotive Industry: Dominated in 2023, using SCARA robots for part assembly, quality inspection, and material handling, especially with the rise of electric vehicles.

- Electrical & Electronics: Expected to grow fastest due to expanding consumer electronics, 5G, and IoT markets requiring high-speed, precision assembly.

- Food & Beverage: Used for precise picking, packaging, and sorting.

- Pharmaceuticals and Medical Devices: Utilized for dispensing, sorting, and packaging.

- Other Industries: Including Metal & Machinery, Rubber & Plastic, and Consumer Goods, also extensively adopt SCARA robots.

Challenges and Restraints

Despite significant growth, the SCARA robot market faces challenges:

- High Initial Investment: The cost of acquiring and integrating SCARA robots can be substantial, limiting adoption for smaller companies.

- Integration Complexity: Integrating robots into existing lines demands specialized expertise and can present interoperability issues.

- Skill Requirements: Programming, maintenance, and troubleshooting SCARA robots require skilled personnel, which can be a limiting factor.

- Limited Degrees of Freedom: SCARAs have fewer degrees of freedom (typically four) than six-axis robots, limiting their applicability to primarily horizontal movements.

Emerging Trends and Opportunities

The future of the SCARA robot market is shaped by exciting trends:

- Collaborative Robotics (Cobots): Integrating SCARA robots with collaborative features is growing. Collaborative SCARA robots work safely alongside humans, enhancing productivity without extensive safety barriers.

- AI and IoT Integration: The preference for SCARA robots with integrated AI and IoT is a major driver. AI enhances efficiency through predictive maintenance and real-time monitoring, while IoT enables seamless smart factory communication.

- Miniaturization and Compact Design: Demand for smaller, more compact SCARA robots is rising for intricate processes and space-constrained environments, particularly in electronics.

- Increased Payload Capabilities: While traditionally for lighter loads, demand for SCARA robots with enhanced handling for higher loads (e.g., above 15kg) is broadening their industry application.

- Growth in SMEs: Increased affordability and ease of programming make SCARA robots more accessible to small and medium-sized enterprises (SMEs), enabling automation without prohibitive capital investment.

Regional Landscape

The SCARA robot market shows distinct regional dynamics:

- Asia-Pacific: Dominated the market in 2023 (over 60% revenue share) due to robust industrial sectors (electronics, automotive), significant automation investments, and government initiatives in China, Japan, and South Korea.

- North America: Expected to grow fast, driven by rising AI-powered robotics adoption, focus on industrial automation, and government support for advanced manufacturing.

- Europe: A prominent market with established industrial bases and growing robot adoption across diverse sectors like healthcare and semiconductors.

Competitive Landscape

The SCARA robot market is highly competitive, featuring major players and innovative EdTech companies. Key providers of SCARA robot solutions include ABB Ltd., FANUC Corporation, Epson Robots, Yaskawa Electric Corporation, DENSO Corporation, Mitsubishi Electric Corporation, Omron Corporation, Yamaha Motor Co., Ltd., Kawasaki Heavy Industries, Ltd., Comau SpA, Stäubli, and Delta Electronics, Inc. These companies continuously innovate and expand through strategic partnerships and acquisitions.

Conclusion

The SCARA robot market is at the forefront of global manufacturing automation. Their unique blend of speed, precision, compactness, and cost-effectiveness makes them indispensable for high-volume, repetitive tasks across critical industries like electronics and automotive. While challenges like initial investment and integration complexities exist, continuous technological advancements—including AI, IoT, and collaborative capabilities—are enhancing their versatility and accessibility. As industries worldwide prioritize efficiency, quality, and adaptability, the SCARA robot market is poised for sustained, significant growth, solidifying its role as a cornerstone of the automated future.

Get More Details : https://www.databridgemarketresearch.com/reports/global-scara-robot-market

Get More Reports :

https://www.databridgemarketresearch.com/reports/global-automated-border-control-market

https://www.databridgemarketresearch.com/reports/global-phosphate-chemical-reagents-market

https://www.databridgemarketresearch.com/reports/global-hdpe-wax-market

https://www.databridgemarketresearch.com/reports/asia-pacific-safety-systems-market

https://www.databridgemarketresearch.com/reports/global-disk-encryption-market