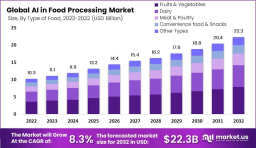

The Global AI in Food Processing Market is projected to grow from USD 11.1 billion in 2023 to USD 22.3 billion by 2032, registering a CAGR of 8.3%. This growth reflects increasing demand for automation, quality control, and operational efficiency across food manufacturing. AI technologies are being integrated into sorting, grading, supply chain optimization, predictive maintenance, and food safety monitoring, enabling data-driven decisions and reduced waste. Rising consumer demand for safe, consistent, and sustainable food products is accelerating adoption. The convergence of AI and Industry 4.0 is transforming the global food processing industry through enhanced precision and scalability.

Key Takeaways:

Market value in 2023: USD 11.1 Billion

Projected value by 2032: USD 22.3 Billion

CAGR (2023–2032): 8.3%

AI improves yield, traceability, and waste reduction

High adoption in quality inspection and predictive analytics

Enhanced productivity through robotics and automation

Demand driven by safety regulations and labor shortages

AI optimizes cold chain logistics and inventory management

Dominant Market Position:

North America dominates the AI in Food Processing market due to its strong technological infrastructure, early AI adoption, and stringent food safety regulations. The presence of major tech innovators and a well-established food manufacturing sector fuels regional leadership. Europe follows closely, driven by regulatory standards and investments in sustainable food systems. Meanwhile, Asia-Pacific is witnessing rapid adoption due to population growth, urbanization, and increasing pressure on food supply chains. Developing economies are leveraging AI to address inefficiencies in food production and distribution, while global firms expand their AI footprint across high-growth emerging markets.

Technology Perspective:

AI technologies such as machine learning, computer vision, and robotics are transforming food processing workflows. Computer vision is used for sorting, grading, and contamination detection, ensuring consistent quality. Predictive analytics supports maintenance and reduces downtime, while AI-driven demand forecasting streamlines production planning. Robotics and automation powered by AI enhance throughput and worker safety. Natural language processing is being integrated into customer-facing applications, aiding product development based on consumer feedback. Cloud computing and IoT devices further enable real-time data analysis and remote process monitoring. Together, these technologies enhance accuracy, reduce costs, and ensure compliance with global food safety standards.

Dynamic Landscape:

The AI in food processing market is marked by cross-sector collaboration, R&D investments, and pilot-to-scale transitions. Startups, food manufacturers, and AI firms are co-developing smart processing systems to boost productivity and reduce waste across the value chain.

Driver, Restraint, Opportunity, Challenge:

Driver: Need for automation and precision to enhance food safety and quality.

Restraint: High initial implementation and integration costs.

Opportunity: Expansion in emerging economies and personalized nutrition.

Challenge: Data standardization, algorithm transparency, and regulatory compliance.

Use Cases:

Visual inspection for defect detection in food items

Predictive maintenance of processing equipment

AI-assisted flavor and recipe development

Robotic sorting and packaging automation

Demand forecasting and inventory optimization

Supply chain traceability and food fraud prevention

AI-powered waste reduction in raw material handling

Personalized dietary recommendations in food production

Key Players Analysis:

Leading players in this market are focusing on AI-powered automation, precision quality control, and smart manufacturing integration. These organizations invest in R&D and cloud-based solutions to improve process intelligence and scalability. Their strategies include partnering with food producers to deploy AI models tailored for sorting, shelf-life estimation, and contamination detection. Their platforms often feature real-time analytics and machine learning-based decision systems, empowering plant managers with actionable insights. The emphasis is on enhancing production efficiency, minimizing losses, and ensuring regulatory compliance. Furthermore, these companies support sustainability goals by reducing energy usage and food waste throughout the processing cycle.

Recent Developments:

Integration of computer vision in real-time food grading systems

Development of AI tools for food spoilage prediction

Launch of robotic arms with machine learning for meat processing

Collaboration between AI and IoT firms for traceable food chains

Cloud platforms introduced for remote monitoring of food operations

AI-powered solutions deployed in temperature-sensitive logistics

Conclusion:

The AI in Food Processing Market is undergoing transformative growth as AI solutions become central to quality assurance, productivity, and sustainability. With rising global food demands and tightening regulations, AI offers a pathway to smarter, safer, and more efficient food production. The future holds significant potential as adoption spreads across geographies and food categories.

| No comments yet. Be the first. |