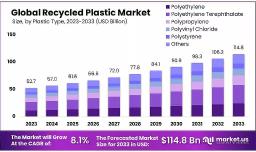

The global Recycled plastics market is projected to grow from approximately USD 52.7 billion in 2023 to nearly USD 114.8 billion by 2033, reflecting a compound annual growth rate (CAGR) of 8.1% over the forecast period. This growth is driven by rising environmental awareness, regulatory pressure to reduce plastic waste, and increasing use of recycled materials across packaging, automotive, and construction industries.

Polyethylene Terephthalate leads the pack accounting for about 29.3% of the recycled plastics market, primarily due to its extensive use in beverage bottles. Other plastic types such as HDPE, PP, and PVC are also seeing strong recycled demand, with HDPE predicted to grow fastest thanks to its durability. The rapid rise of e-commerce and online sales is contributing to demand for packaging materials, further driving this market forward.

Key Takeaways:

https://market.us/wp-content/uploads/2023/11/Recycled-Plastic-Market-1024x608.jpg" alt="Recycled Plastic Market" width="1024" height="608"> Download Exclusive Sample Of This Premium Report:

https://market.us/report/recycled-plastics-market/free-sample/

Key Market Segments:

One of the main forces driving the recycled plastics market is the rising concern over plastic pollution and its environmental impact. Governments and global organizations are pushing for strict regulations to limit single-use plastics and encourage recycling efforts. This is compelling manufacturers across industries from packaging to automotive to adopt recycled plastics as a sustainable alternative. Consumer awareness has also surged, with more people actively choosing products made from recycled materials, especially in packaging, where demand for eco-friendly options is highest.

The booming e-commerce sector has significantly increased the demand for protective packaging, often made from plastics. As companies aim to reduce their carbon footprint, they’re turning to recycled plastics for both environmental and branding benefits. Furthermore, technological improvements in collection and sorting processes are making it easier to recycle different plastic types like PET, HDPE, and LDPE, contributing to more efficient material recovery.

Despite promising growth, several challenges restrict the full potential of the recycled plastics market. One of the biggest hurdles is the quality and consistency of recycled material. Plastics degrade during recycling, especially when mechanically processed, which limits the number of times they can be reused and may affect the final product quality.

Another issue is the economic feasibility of recycling. Recycled plastic is sometimes more expensive than virgin plastic due to complex processing, contamination issues, and fluctuating raw material costs. This price gap often discourages industries from fully switching to recycled options.

The lack of standardized sorting and collection systems, especially in developing countries, results in low recycling rates and poor-quality feedstock. Moreover, limited public awareness and participation in recycling programs can slow down collection efforts. Certain plastic types, such as multi-layer packaging, remain non-recyclable or extremely difficult to process, contributing to continued landfill accumulation. Finally, regulatory uncertainty in some regions, or the absence of clear guidelines around recycled content requirements, may hinder long-term planning and investment in recycling technologies.

A major opportunity lies in the advancement of chemical recycling technologies, which allow for the processing of contaminated or mixed plastics that are difficult to recycle mechanically. This opens the door to a wider range of waste streams being converted into high-quality raw materials. These methods are still being developed and scaled, but they hold promise for boosting recycling rates and reducing dependence on virgin plastics.

There is also considerable opportunity in emerging markets, particularly in Asia-Pacific and parts of Africa and Latin America, where recycling infrastructure is growing. As governments in these regions implement plastic waste management policies, recycled plastics can become a vital resource. Industries such as construction, electronics, and automotive are increasingly using recycled plastics in structural components and interior materials, expanding their applications.

Innovations in biodegradable and bio-based plastics also intersect with recycled plastic usage, offering hybrid solutions that could become mainstream. Finally, partnerships between public bodies and private companies can help build the necessary infrastructure for large-scale collection and processing, creating new revenue streams and job opportunities.

One of the leading trends shaping the recycled plastics market is the circular economy model, where the focus is on reusing and recycling materials continuously to reduce waste. More companies are setting sustainability goals that include using a specific percentage of recycled content in their products.

Digital technology is also playing a role smart waste sorting using AI, machine vision, and robotics is improving the speed and accuracy of recycling operations. Blockchain is being explored to track plastic usage and recycled content more transparently across supply chains.

Another trend is the collaboration across industries to develop closed-loop recycling systems. Brands are working directly with recyclers to ensure a steady supply of post-consumer plastic that meets their product standards. Also, the fashion and textile industries are emerging as new consumers of recycled plastics, using them in synthetic fabrics and footwear. Consumer preference is shifting toward eco-friendly packaging, and this behavioral trend is encouraging retailers and manufacturers to rethink how they package and ship goods. As a result, recycled plastic use is expanding into more product categories.

The recycled plastics market is on a strong path of growth, with projected value expected to more than double by 2033. Environmental regulations and corporate sustainability goals are driving higher recycled content use, particularly in PET packaging. Innovation in chemical recycling and new market applications like automotive and construction offer fresh avenues for expansion.

To maintain momentum, the industry must tackle quality, cost, and infrastructure challenges. Improving sorting, adopting scalable technologies, and aligning with circular economy policies are crucial. With strategic investment in recycling systems and growing demand from key regions like Asia-Pacific, the recycled plastics industry is positioned to deliver both economic and environmental benefits in the decade ahead.

| No comments yet. Be the first. |